品牌:2176

不锈钢板式冷却器 换热器厂家

不锈钢板式冷却器 换热器厂家

不锈钢板式冷却器 换热器厂家

一、产品简介

板式冷却器是由框架、传热板片组及夹紧螺栓等主要部件组成。

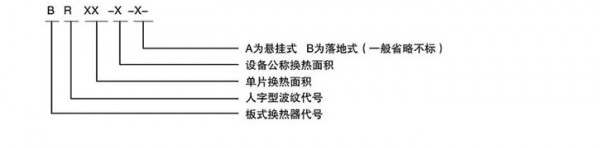

型号Model BR0.12

单片有效面积Active Area Per Plate 0.12m2,

板片波纹深度Nominal plate gap 2.8mm

板片厚度Thi ckne ss 0.5mm

板片角孔尺寸Port dim 50mm

最大流量Max flow rate 51M3/H

接管口径Co

工作压力Working pressure 0.6MPa、1.OMPa、1.6MPa

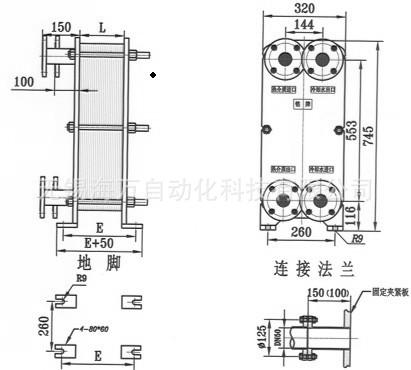

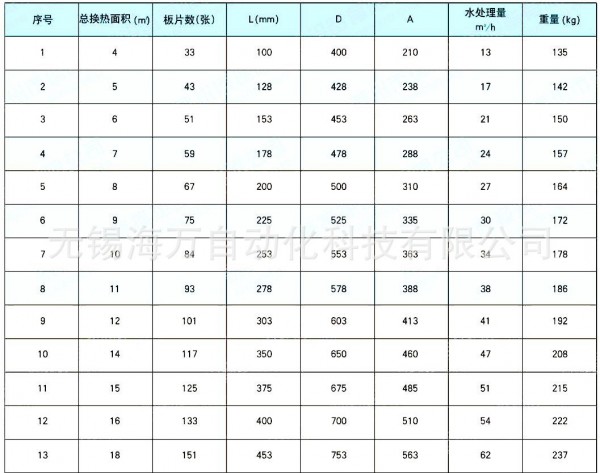

二、BR冷却器型号尺寸、参数表

三、板式换热器的技术优势和特点:

1、传热系数高:传热板片上的特殊波纹设计,可使流体在极低的流速下产生强烈的湍流,湍流的自净效应又可防止污垢的产生,使得板式换热器的传热系数为管壳式换热器的3-5倍。

2、经济性:相同换热量的前提下,与管壳式比较:投资少、运行费用低、维修费用低。

3、可调整性:只需增加和减少板片即可满足工艺过程改变的需求。

4、结构紧凑:在相同换热量的前提下,占用空间仅为管壳式的1/2一l/3。

四、板式换热器设计理念:

1、板片带有增压的新型导流区设计是在板片导流区流速较大的地方采用多路通道增加压力,使整张板片中的流速达到均等,大大提高了板片的换热效率,减少了死角,改善了板片的结垢状况。

2、板片高强度挂口设计是在挂口处增加花纹设计,加强翻边周围的刚性,组装起来更加整齐美观、打开性能更好。

3、板片中间部位板槽设计足把板片内部的连续波纹断开,并存板片I}l增加了半槽结构,缓和板片所承受的压力,使板片压制成形后更、卜整,小易弯曲。

4、板片互锁设计是在板片的四角压制特殊的机械互锁结构,改善了板片组装过程中容易串位泄露的现象,使板片组装起来更加便捷、美观。

5、板片密封垫片全部采用免粘贴搭扣形式,减少运行维护成本,便于维修。

叶片泵,齿轮泵,柱塞泵,双联叶片泵,定量叶片泵,双联变量叶片泵,双联齿轮泵,油泵,齿轮油泵,齿轮马达,液压马达,高压齿轮泵,高压齿轮马达,油泵电机组厂家无锡海万;

电磁阀,脉冲阀,脉冲控制仪,膜片,气控阀,截止阀,截止式换向阀,人控阀,机械阀,手转阀,角座阀,制冷电磁阀,膜片电磁阀,法兰电磁阀,减压阀,调压阀,油雾器,过滤器,空气过滤器,二联件,三联件,气源处理组合,除油器厂家无锡海万;

液压附件,蓄能器,蓄能器安全阀组,截止阀安全阀组,过滤器,过过器滤芯,冷却器,风冷机,液位计,温度计,滤清器厂家无锡海万;

电磁制动器,电磁失电制动器,电磁离合器,多片电磁离合器,牙嵌式电磁离合器,多片多片电磁离合器,干片电磁离合器,快速电磁离合器,单片电磁离合器器,整流器,整流装置,碳刷,电刷,制动器厂家无锡海万。本公司产品质量保证,价格优惠,品种齐全,销往全国各地。

可订货型号:

BR0.65-110,BR0.65-115,BR0.65-120

BR0.65-65,BR0.65-70,BR0.65-75

BR0.65-80,BR0.65-90,BR0.65-100

BR0.65-50,BR0.65-55,BR0.65-60

BR0.65-35,BR0.65-40,BR0.65-45

BR0.23-12,BR0.23-14, BR0.23-16

BR0.23-24,BR0.23-26, BR0.23-28

BR0.23-30, BR0.23-35

BR0.23-18,BR0.23-20,BR0.23-22

BR0.23-8,BR0.23-9, BR0.23-10

BR1.0-70,BR1.0-80,BR1.0-90

BR1.0-100,BR1.0-110,BR1.0-120

BR1.0-140,BR1.0-150,BR1.0-160

BR1.0-180,BR1.0-200,BR1.0-210

BR1.0-220,BR1.0-230

BR0.6-50,BR0.6-55, BR0.6-60

BR0.6-90,BR0.6-100

BR0.6-65,BR0.6-70, BR0.6-80

BR0.6-30,BR0.6-40, BR0.6-45

BR0.15-16,BR0.15-18, BR0.15-19,BR0.15-20

BR0.15-7,BR0.15-9, BR0.15-11

BR0.15-4,BR0.15-5, BR0.15-6

BR0.15-13,BR0.15-14, BR0.15-15

BR0.35-45,BR0.35-50

BR0.35-20,BR0.35-22 ,BR0.35-24

BR0.35-30,BR0.35-35 ,BR0.35-40

BR0.35-25,BR0.35-26 ,BR0.35-28

BR0.35-15,BR0.35-16 ,BR0.35-18

BR0.12-7,BR0.12-8,BR0.12-9

BR0.12-10,BR0.12-11,BR0.12-12

BR0.12-4,BR0.12-5,BR0.12-6

BR0.12-18

BR0.12-14,BR0.12-15,BR0.12-16

BR0.5-70,BR0.5-75,BR0.5-80

BR0.5-85,BR0.5-90

BR0.5-25,BR0.5-30,BR0.5-35

BR0.5-40,BR0.5-45,BR0.5-50

BR0.5-55,BR0.5-60,BR0.5-65

BR0.05-1.5,BR0.05-2.0

BR0.05-0.5,BR0.05-0.75,BR0.05-1.0

BR0.05-4.0,BR0.05-4.5,BR0.05-5.0

BR0.05-2.5,BR0.05-3.0,BR0.05-3.5

BR0.55-50, BR0.55-55,BR0.55-60

BR0.55-80, BR0.55-85,BR0.55-90

BR0.55-95, BR0.55-100

BR0.55-35, BR0.55-40,BR0.55-45

BR0.55-65, BR0.55-70,BR0.55-75

BR0.8-100,BR0.8-110,BR0.8-120

BR0.8-50,BR0.8-60,BR0.8-65

BR0.8-70,BR0.8-75,BR0.8-80

BR0.8-140,BR0.8-150,BR0.8-160

BR0.8-85,BR0.8-90,BR0.8-95

BR1.3-180,BR1.3-200,BR1.3-220

BR1.3-130,BR1.3-140,BR1.3-150

BR1.3-100,BR1.3-110,BR1.3-120

BR1.3-250,BR1.3-300

BR0.1-8,BR0.1-9,BR0.1-10

BR0.1-11,BR0.1-12,BR0.1-13

BR0.1-5,BR0.1-6,BR0.1-7

BR0.1-2,BR0.1-3,BR0.1-4

BR0.1-14

BR0.2-5,BR0.2-6,BR0.2-7

BR0.2-12,BR0.2-15,BR0.2-16,BR0.2-18

BR0.2-8,BR0.2-9,BR0.2-10

BR0.2-20,BR0.2-22,BR0.2-24,BR0.2-25

BR0.37-26, BR0.37-28, BR0.37-30

BR0.37-16, BR0.37-18, BR0.37-20

BR0.37-50, BR0.37-55

BR0.37-35, BR0.37-40, BR0.37-45

BR0.37-22, BR0.37-24, BR0.37-25

BR1.6-120,BR1.6-130,BR1.6-140

BR1.6-350,BR1.6-400

BR1.6-150,BR1.6-180,BR1.6-200

BR1.6-225,BR1.6-250,BR1.6-300

BR0.25-34, BR0.25-35

BR0.25-22,BR0.25-24, BR0.25-25

BR0.25-10,BR0.25-12, BR0.25-14

BR0.25-28,BR0.25-30, BR0.25-32

BR0.25-15,BR0.25-18, BR0.25-20